A firearm is more than a tool; it’s a piece of engineering. Understanding how materials and manufacturing processes contribute to a firearm’s durability, feel, and price adds a new level of appreciation for shooters and collectors alike.

The journey from raw materials like metal or polymer to a finished firearm involves complex metallurgy, chemistry, and machining.

The Foundation: Common Firearm Materials

The materials chosen for a firearm dictate its weight, durability, recoil management, and longevity. Manufacturers must balance strength with machinability and cost. Here are the primary materials you will encounter.

Steel: The Traditional Standard

Steel has been the backbone of gunsmithing for centuries. However, not all steel is created equal. Gunmakers utilize specific grades of carbon and stainless steel designed to withstand high pressure and friction.

- Carbon Steel: Known for its immense strength and ease of machining, carbon steel (often 4140 or 4150 chrome-moly) is a favorite for barrels and receivers. It is durable and takes bluing well, but it is susceptible to rust if not properly maintained.

- Stainless Steel: offering superior corrosion resistance, stainless steel (often 416 or 17-4 PH) is popular for firearms used in humid environments or for carry guns exposed to sweat. While slightly more difficult to machine than carbon steel, it requires less external finishing to prevent rust.

Aluminum Alloys: Lightweight Strength

As the demand for lighter carry weapons grew, aluminum alloys entered the scene. Specifically, 7075-T6 and 6061-T6 aluminum are industry standards for receivers and frames. These alloys offer a fantastic strength-to-weight ratio.

They are significantly lighter than steel but strong enough to handle the mechanical stress of firing, provided they are used in non-pressure-bearing components like the lower receiver of a rifle or the frame of a pistol.

Polymers: The Modern Revolution

The introduction of the Glock in the 1980s popularized the use of high-strength polymers in firearm frames. Today, modern engineering plastics like glass-filled nylon are ubiquitous. These materials are impervious to rust, extremely lightweight, and possess a slight flexibility that helps dampen recoil.

Far from being “cheap plastic,” these polymers are chemically engineered to survive extreme temperatures and rough handling.

Shaping the Steel: Manufacturing Processes

Once the materials are selected, they must be shaped into complex components. This is where manufacturing methodologies come into play.

Forging

Forging involves heating metal until it is malleable and then hammering or pressing it into shape using massive dies. This process aligns the grain structure of the metal, resulting in exceptionally strong parts.

Forged receivers and barrels are prized for their durability and resistance to impact. If you buy a high-end rifle, there is a good chance the critical components started as forgings.

Casting

Investment casting involves pouring molten metal into a mold. This allows for intricate shapes that would be difficult or expensive to machine from a solid block.

While cast parts are generally not as strong as forged ones due to a more random grain structure, modern casting technology produces components that are more than adequate for most firearm applications. It is a cost-effective way to produce complex parts like trigger guards or revolver frames.

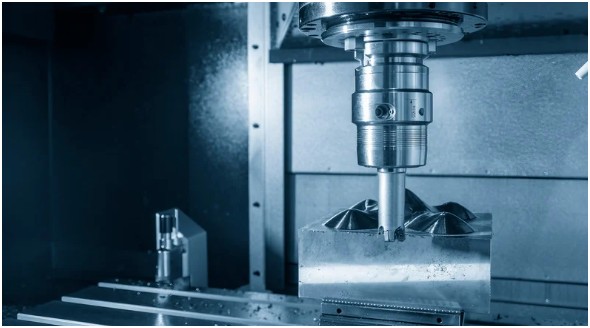

CNC Machining

Computer Numerical Control (CNC) machining is the standard for precision. Whether starting from a solid block of billet metal, a forging, or a casting, CNC machines cut away excess material with incredible accuracy. This ensures that every slide fits every frame and that tolerances are kept within thousandths of an inch.

Billet receivers, which are machined entirely from a solid block of metal, are often sought after for their aesthetic perfection and precise dimensions.

Hardening the Core: Heat Treatment and Finishing

A machined part is not yet ready for the firing line. It needs to be toughened and protected.

Heat Treatment

Heat treating is arguably the most critical step in ensuring safety and longevity. By heating the metal to specific temperatures and cooling it at controlled rates (quenching), manufacturers can alter the metal’s molecular structure.

- Hardening: Makes the metal resistant to wear.

- Tempering: Relieves internal stresses caused by hardening, making the metal less brittle so it won’t shatter under impact.

Improper heat treatment is often the culprit when gun parts fail catastrophically, which highlights why quality control in this phase is paramount.

Surface Finishing

Since raw steel rusts and raw aluminum oxidizes, surface finishes are applied for protection and aesthetics.

- Bluing/Parkerizing: Traditional chemical conversion processes that offer basic corrosion resistance for steel.

- Anodizing: An electrochemical process used on aluminum to create a hard, wear-resistant surface layer.

- Nitriding (Melonite/Tenifer): A surface hardening treatment that diffuses nitrogen and carbon into the steel, creating incredible hardness and corrosion resistance.

- Cerakote: A ceramic-based spray-on coating that comes in various colors and offers excellent protection against chemicals and abrasion.

The Cutting Edge: Modern Innovations

The firearm industry is not stagnant. New technologies are pushing the boundaries of what is possible.

Metal Injection Molding (MIM)

MIM involves mixing fine metal powder with a binder material to create a “feedstock” that is injected into a mold, similar to plastic injection molding. The part is then heated to remove the binder and sinter the metal particles together.

MIM allows for the mass production of small, complex parts like safety levers and mag catches at a low cost. While purists sometimes debate its durability compared to machined steel, MIM technology has improved drastically and is used by major manufacturers for non-critical small parts.

Additive Manufacturing (3D Printing)

3D printing is no longer just for prototyping. High-end metal 3D printers can now print inconel and titanium suppressors and other complex components that cannot be made via traditional machining. In the consumer space, printing accessories or even frames has become a massive hobbyist movement.

For instance, you might see a customized AR-15 stock or a vertical grip that was printed at home, allowing for a level of personalization previously impossible without expensive tooling.

Exotic Materials

While steel and aluminum dominate, high-end applications are seeing the use of titanium and carbon fiber. Titanium offers the strength of steel at half the weight, while carbon fiber wrapped barrels provide rigidity and heat dissipation without the heft of a heavy bull barrel.

Conclusion

The manufacturing of firearms is a study in compromise and precision. It is about balancing the unstoppable force of an explosion with the immovable object of the chamber. From the grain structure aligned by a heavy forge to the microscopic precision of a CNC cutter, every step matters.